CAM divider is also called CAM divider and intermittent divider in engineering. It is a kind of high precision rotary device, in the current automation requirements, the CAM classifier is particularly important.

First, the working principle of the CAM divider

The working principle of the CAM divider is that the conjugate CAM on the input shaft engages vertically with the index plate with uniform distribution of needle roller bearings on the output shaft without clearance, the curve section of the CAM contour surface drives the needle roller bearing on the index plate to drive the index plate to rotate, and the straight section makes the index plate static and positions itself to lock.

Under normal circumstances, the input axis rotates once (360°), and the output axis completes a indexing process with a stop. In a indexing process, the output axis has a ratio of rotation time and stop time called the ratio of static and dynamic, and the size of the ratio of static and dynamic is related to the Angle size of the CAM curve segment on the whole CAM circumference (usually the Angle of this curve is called the drive Angle). The larger the driving Angle, the larger the ratio, the smoother the operation of the divider.

Second, the category of the divider

1, spindle splitter -DS series

1) This series of machine is a typical traditional mandrel model, and its output shaft has a small rotational inertia, so it is suitable for high-speed rotation action;

2) The processing and installation of gear, coupling or coupling disc of its installation accessories, need to pay special attention to aperture tolerance and keyway tolerance;

3) Its use is mostly in intermittent conveyor belt drive, gear drive, and non-clearance coupling combined drive.

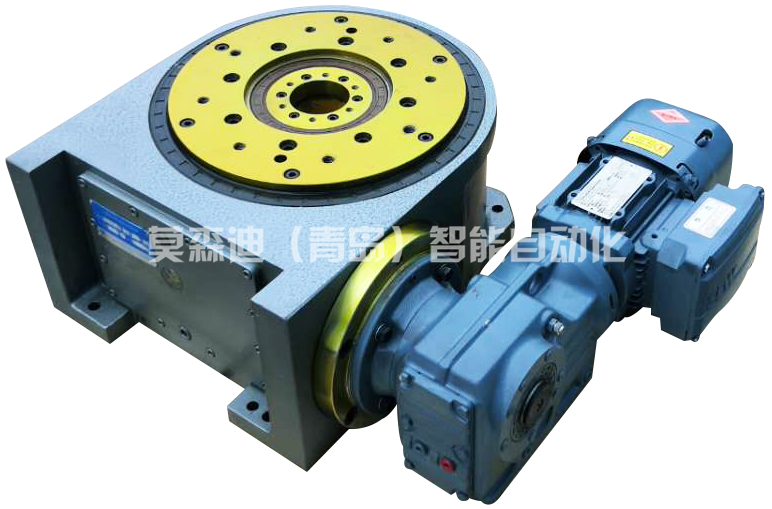

2, flanged splitter -DF series

(1) This type of machine has heavy load characteristics, can withstand large vertical radial or axial pressure;

(2) The output shaft is disk type design, with flange center, disk screw hole, positioning, pin hole, fixing surface wide, can make flatness and stability, more solid and stable. Suitable for large load rotary disk drive occasions;

(3) This series of machines is widely used in all kinds of disk processing machinery, and similar institutions of industrial machinery, automatic intermittent drive, drive disk;

(4) The output shaft can be perforated in the middle, and the actual hollow size is selected according to the model.

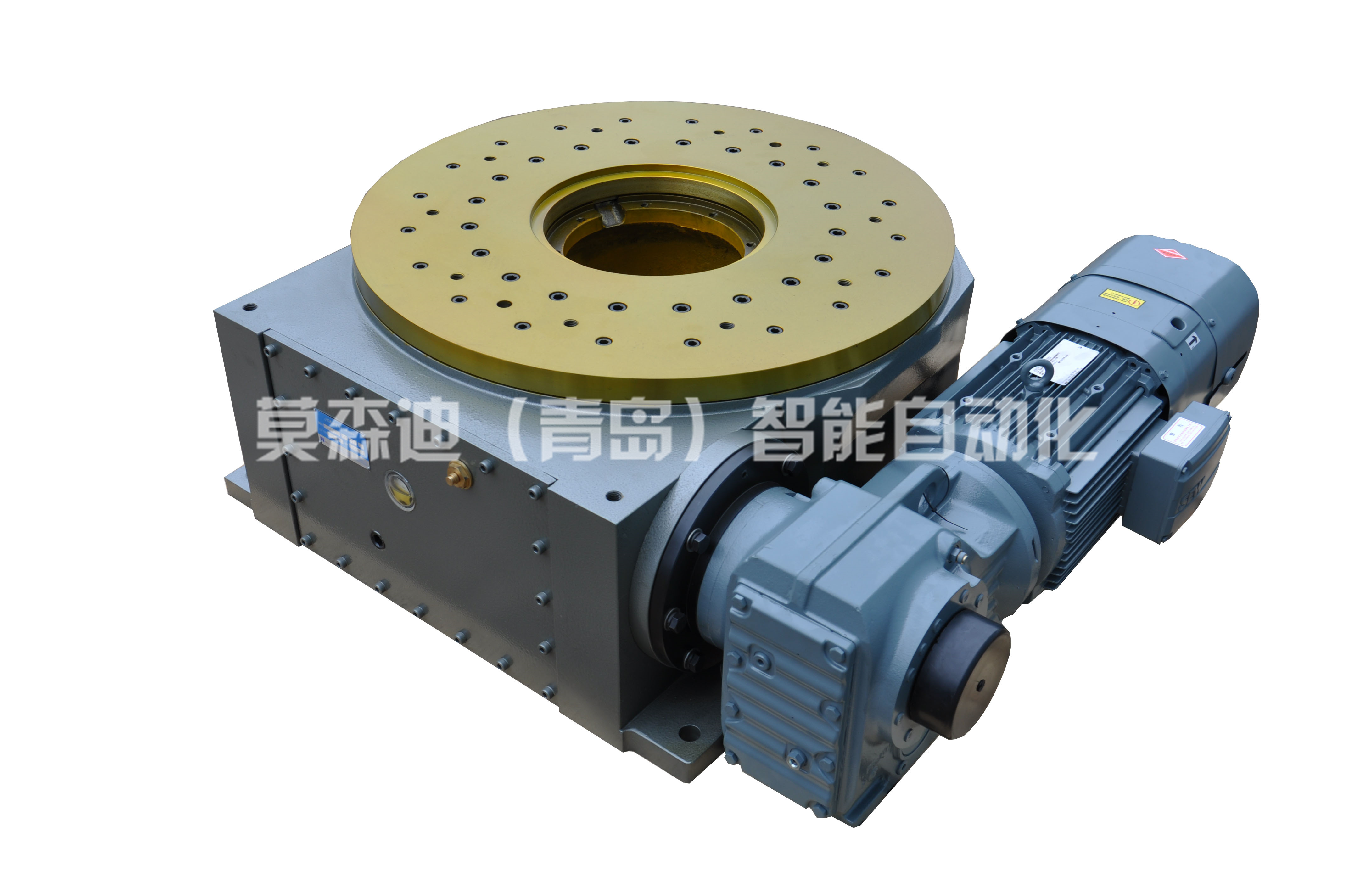

3, platform desktop splitter -DT series

(1) The dimensional design characteristics of this series of machines are similar to the function of the flange type, which can withstand large axial load and vertical radial pressure on the driving operation;

(2) At the output end, there is a convex fixed disk surface and a large diameter hollow shaft, which can be configured with dynamic and static automation peripheral equipment, and the electricity, oil, gas and other pipelines of the power source can be placed in the hollow hole;

(3) This series of machine is widely used in heavy load, straight junction automation equipment of all kinds of institutions and industrial machinery, as synchronous automation intermittent drive;

(4) It can be equipped with two disks, the middle small flange is stationary, and the big flange is rotating.

4, ultra-thin platform desktop splitter -DA series

1) The dimensional design characteristics of this series of machines are similar to the function of the platform desktop type, which can withstand large axial load and vertical radial pressure on the driving operation;

2) There is a convex fixed disk and a large diameter hollow shaft at the output end, which can be configured with dynamic and static automation peripheral equipment, and the electricity, oil and gas pipe of the power source can be set in the hollow hole;

3) It can be equipped with two disks, the middle small flange is stationary, and the big flange is rotating;

4) The overall size is relatively small, which can effectively save space.